An In-depth Look Into Green Hydrogen

The moment has come to capitalise on hydrogen’s potential to play a leading role in addressing crucial energy concerns. The recent advances in renewable energy technologies and electric vehicles have demonstrated that policy and technological innovation have the potential to create global clean energy enterprises.

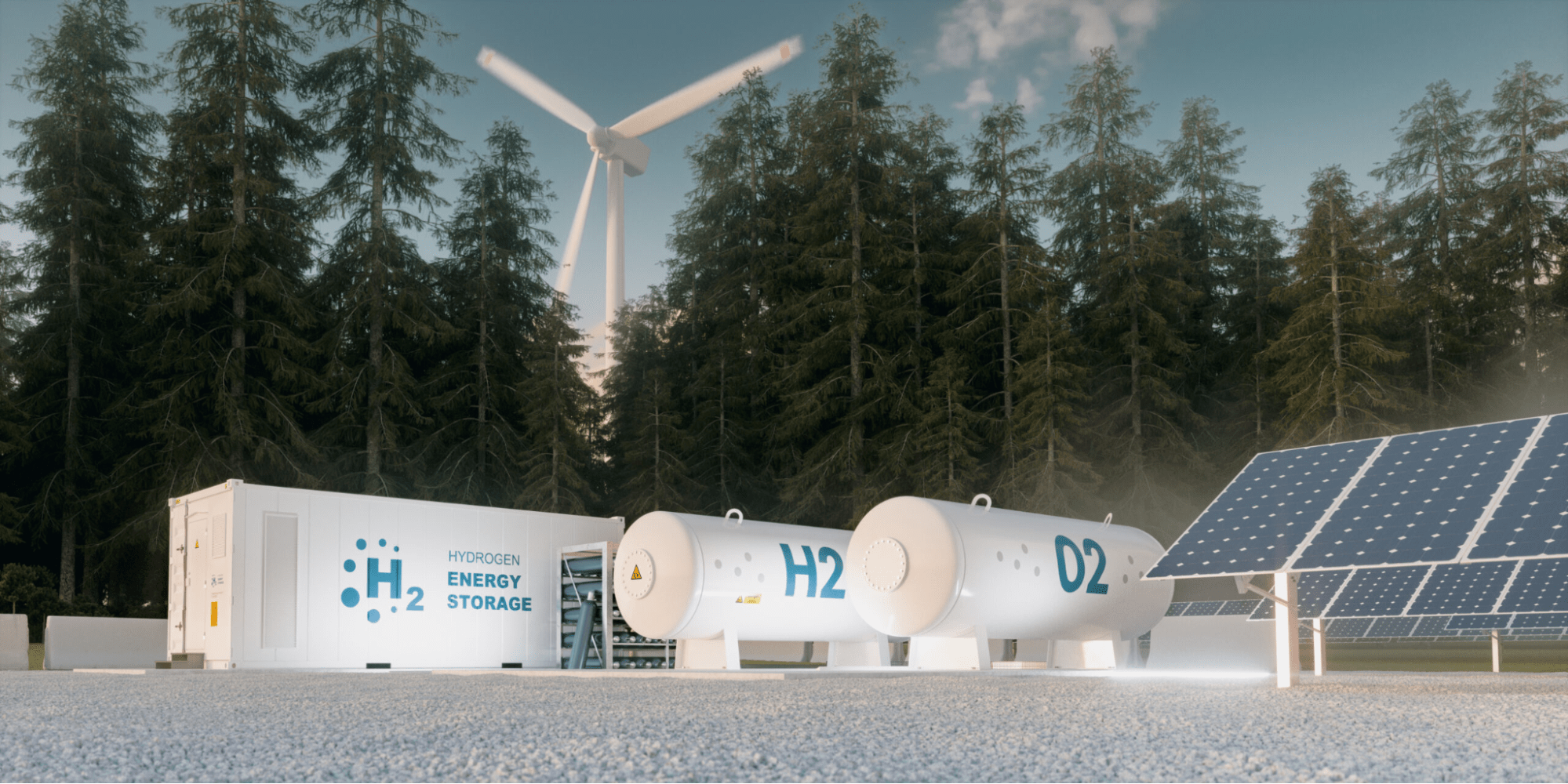

With hydrogen-based fuels possibly delivering energy from renewables across vast distances – from locations with ample energy resourced locations to energy-hungry areas thousands of miles away – hydrogen is emerging as one of the top options for storing energy from renewables.

Green hydrogen was mentioned in several pledges to reduce emissions at the UN Climate Conference, COP26, as a way to decarbonise heavy industry, long-distance freight, shipping, and aviation. Hydrogen has been recognised as a crucial component of a net-zero economy by both governments and businesses.

The Green Hydrogen Catapult, a United Nations programme aimed at lowering the cost of green hydrogen, said that it is nearly tripling its goal for green electrolysers from 25 gigatonnes established last year to 45 gigatonnes by 2027. The European Commission has adopted a package of legislative recommendations to decarbonise the EU gas market by enabling the use of renewable and low-carbon gases such as hydrogen.

Likewise, the United Arab Emirates is also raising its ambitions, with its new hydrogen strategy aiming to capture one-fourth of the global low-carbon hydrogen market by 2030. In addition, last year, Japan announced a $3.4 billion investment from its green innovation fund to accelerate research and development and promote hydrogen use over the next ten years.

WHAT IS GREEN HYDROGEN AND HOW DOES IT VARY FROM TRADITIONAL, HIGH-EMISSIONS ‘GREY’ AND ‘BLUE’ HYDROGEN?

When discussing hydrogen technology, you may come across the terms ‘grey,’ ‘blue,’ and ‘green.’ It all comes down to how the hydrogen is made.

When burned, hydrogen emits simply water, although its production can be carbon-intensive. Depending on the manner of synthesis, hydrogen can be grey, blue, or green — and occasionally pink, yellow, or turquoise.

Green hydrogen, on the contrary, is the only form produced in a climate-neutral manner, making it crucial to achieve net-zero by 2050.

The smallest and simplest element in the periodic table is hydrogen. It produces the same carbon-free molecule regardless of how it is made. However, the processes through which it is produced are extremely diverse, as are the emissions of greenhouse gases such as carbon dioxide (CO2) and methane (CH4).

Green hydrogen is hydrogen created by splitting water into hydrogen and oxygen using renewable energy – a completely different path from both grey and blue.

Grey hydrogen is produced by splitting methane (CH4) with steam to produce CO2 – the primary cause of climate change – and H2, hydrogen. Grey hydrogens chief source is coal, with much higher CO2 emissions per unit of hydrogen produced, so much so that it is often referred to as brown or black hydrogen rather than grey hydrogen. It is generated on an industrial scale, with emissions comparable to the combined emissions of the United Kingdom and Indonesia.

Similarly, Blue hydrogen is manufactured in the same way as grey hydrogen, but with the addition of carbon capture and storage (CCS) technology. It is not a single colour but rather a gradation, because not all CO2 created can be captured, and not all methods of storing it are equally successful in the long run. The essential idea is that by trapping a considerable portion of the CO2, the climate impact of hydrogen production may be decreased significantly.

There are technologies (e.g., methane pyrolysis) that hold the promise of high capture rates (90-95%) and successful long-term storage of CO2 in solid form, possibly far superior to blue and deserving of their own colour in the “hydrogen taxonomy rainbow,” turquoise hydrogen.

Methane pyrolysis is still at the pilot stage. Yet, green hydrogen is rapidly scaling up based on two chief technologies: renewable power (particularly solar PV and wind, but not exclusively) and electrolysis.

Unlike renewable energy, which is now the cheapest source of electricity in most nations and regions, electrolysis for green hydrogen generation must be extensively scaled up and reduced in cost by at least thrice over the next decade or two. However, electrolysis is commercially available now from numerous foreign providers.

HOW CAN WE TRANSITION FROM GREY HYDROGEN TO A GREEN HYDROGEN ECONOMY?

Green hydrogen is a critical component in the energy transition but it is not the next immediate step – we must first expedite renewable energy deployment to decarbonise present power systems. It will be followed by electrification of the energy sector to utilise low-cost renewable electricity. Finally, green hydrogen will then be used to decarbonise difficult-to-electrify sectors such as heavy manufacturing, shipping, and aviation.

It is crucial to emphasise that we now produce a substantial quantity of grey hydrogen, which emits significant amounts of CO2 (and methane): the goal would be to begin decarbonising existing hydrogen demand, for example, by substituting ammonia from natural gas with green ammonia.

THE FUTURE OF GREEN HYDROGEN

Several governments, including the UK, have incorporated hydrogen fuel technologies into their national policies. But, to achieve net-zero emissions, particularly in industry, shipping, and aircraft, EGB believes the following is required urgently:

Energy efficiency;

Immediate electrification;

The rapid expansion of renewable energy generation.

Once accomplished, we’ll be left with approximately 40% of the demand to decarbonise. It is where green hydrogen, contemporary bioenergy, and direct usage of renewables come into play. With the proliferation in renewable power capacity to decarbonise electricity, we will be able to increase manufacturing competitive green hydrogen and decarbonise difficult-to-abate sectors at low additional cost.

ABOUT EGB ENGINEERING

EGB Engineering is a global engineering consulting firm specialising in sustainable energy solutions, power and propulsion systems. We work in the energy, aerospace, and nuclear industries, providing clients with sustainable and renewable engineering products and services.